|

|

|

|

|

|

|

WELCOME! |

CONTACT! ....thoughts from the Director |

||||||||

|

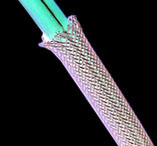

· Is solid or twisted wire too heavy for your needs; is it too fragile and breaks down after repeated bends? · Or maybe you can't reach optimum electrical or mechanical performance with your current wire choice? · Are you sacrificing attributes and making expensive tradeoffs? Now is the time to investigate metal-coated or conductive yarns

and fibers and see why they are rapidly becoming the smart choice for

engineers and designers in a variety of areas: such as aircraft, space, smart

clothing, EMI* shielding, and much, much more. The newest developments are witnessing

conductive fibers becoming fibrous circuits—truly integrated

electronics. |

|

This continues to be an ever more exciting time for conductive and metal clad/metal coated fibers—often called flexible electronics. In addition to a constant stream of new discoveries, techniques and base materials, there are a plethora of smart fabrics and products on the market, and all buttressed by an increasing number of trade shows and events--all opportunities for professionals to interact. LinkedIn, the venerable and premier business contact website, also offers Groups in the areas of wearable electronics and smart fabrics. How BIG is this market? The newest data state that the conductive textile is projected to grow to US $4.9Billion by 2031. And these numbers only represent the smart fabrics portion of the conductive fiber/film market, not the portion for conductive wires used for aircraft and space shielding! Post-COVID expects continued growth due to needs in electronic innovations, smart carts, increased space travel, and greater sophistication in international technology development. We just attended an IFAI exhibit. My overall observation is that smart fabrics are mature, no longer flash-in-the-pan. There are fewer "gee-whiz" dreamers but are more serious products. But the big breakthrough is yet to happen, because the conductive fibers, sensors, materials are not yet optimally integrated. It's coming...and an exciting time to be on the ground floor. Meanwhile the basic electronic (non-textile) industry is more attuned to conductive fibers and flexible electronics than ever. In fact, the NEXT BIG THING will not be just passive coated fibers, but fibers with embedded electronics, fibers and cloths that do things. We are now seeing photovoltaic fibers, battery and capacitance fibers, RFID-embedded fibers, lit fibers. Soon your earring or clip on-chip will be your Bluetooth earphone and microphone. |

|||||||

|

|

This web site is brought to you by member conductive or metal

coated yarn and fiber manufactures, researchers, industry vendors, and others

to increase the awareness of, knowledge about, and utilization of conductive

fibers. We want to eliminate tradeoffs and help you optimize your

conductivity choices.

|

|

"The

trend in (high perfomance wiring) continues to be SWaP--reduced size,

weight, and power," says J.C. Ramirez at ADL Embedded Solutions

in San Diego. And SWaP is the keyword, and the basis of our

industry--conductive fibers reduce weight, increase strength and

flexibility." BUT, today, for the smart fabrics industry, we

want to add two more key words: Comfort and Functionality. |

||||||

|

Feel free to contact us with questions or tell us how this website can better serve your needs. |

Click on our CONNECTIONS tab on top (or here) for the latest conductive/metal coated fiber, yarn Industry News |

||||||||

|

© CFMC, 2009-2024 Conductive Fiber Manufacturers Council™ (spark image © IStock), website by TMMS |

|||||||||